Quick Notice: This article focuses on the UK Martindale masks, not the respirators produced by MECO, Martindales' USA based parent company.

The Martindale Protective Masks were a series of dust masks that were produced by Martindale Electric Co - the UK based offshoot of Martindale Electric Company Inc (Meco) whom were based in Ohio, USA. More specifically, they were produced by Martindale's safety equipment division: Martindale Protection LTD.

Production History[]

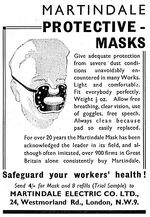

These masks were probably first produced in 1928, the year of founding for Martindale Electric Co. A Martindale poster dated 1950 states For over 20 years... which would imply an original production date of circa 1928.

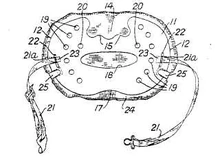

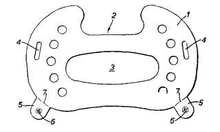

Original 1937 patent drawing

Martindale Electric Co would file their first UK patent on 31st March 1937, Improvements in or relating to sanitary masks and respirators which was filed by Harry Johnson, an employee of Martindale.

Several other patents for various new designs were filed by Martindale employee Frederic Stanley throughout the 1950s and 1960s. These designs are further explored below.

Mask overview[]

Closeup of respirator

The mask is a typical example of a half-face respirator design - featuring only three components: The filtering pad/medium, the face-plate and an elasticated headband with adjustment buckles.

A paper packet containing the mask

The face-plate is constructed of a malleable metal or plastic, depending on the specific model. The face-plates feature a recess in the shape of a 'U' - this is the recess for the wearers nose to sit. Some Martindale models also had small projections in the bottom of these recesses to sit inside the nostrils - a kind of pseudo nose-clip. On the original 1937 patent, these nostril projections can be seen labelled '15' (see above photo).

Some models of Martindale mask feature small perforations running the length of the mask in a curved line. This was probably done to decrease breathing resistance.

Headband closeup

Martindale face-plates feature a slit cut into the metal in order to thread the headband through. The headbands were usually made of a black elasticated fabric and had a hook and clip to tie the headband together.

An example of the gripping tabs

These face-plates often featured a projected tab from the face-plates' periphery. These tabs were designed to be bent inwards to grip the filter pad into place, and could be unbent to release the pad for a new one.

A large central hole features on the face-plates. This was a mouth opening, and was probably designed to increase audible speech and was the main air intake area on the mask.

The masks were supplied in grease-proof paper packets with an informational card.

Filter[]

The 1937 patent states the filter is to be constructed of cotton-wool covered in gauze. Additionally, the patent suggests the filter pad construction can include fireproofed materials. Although 'fireproof materials' is fairly non-specific, it may allude to this material being asbestos. Asbestos' fire-resistant properties (which became well-known in the early 1900s), coupled with its fairly cheap production rates make asbestos a likely candidate for the patents mystery 'fireproofed materials'. Moreover, the technique of creating a particulate filter consisting of asbestos woven into wool was already well underway in other British respirators - chiefly the British Civilian Duty Respirator and British General Civilian Respirator.

On 5th September 1963 two Martindale employees, Stanley Gerrish and Frederic Stanley, filed a patent for Filter pads for sanitary masks and sanitary masks incorporating such pads. This patent states the filters were to be constructed of either cotton-wool, medical gauze, or resin-impregnated Merino wool. These layers were to be sandwiched between two layers of flexible polyurethane.

Gerrish and Stanley's 1963 patent also gives insight into how such filtering pads were constructed at Martindale. The wool layer and polyurethane layers were assembled in a frame and held together via pins. An electronically heated knife then welded and cut the pads to shape. The patent also claims the layers can also be welded by mechanical pressure alone.

These filter pads were not designed for particularly dense contamination; later face-plates have 'FOR NUISANCE DUSTS ONLY' etched on them.

Variants by Frederic Stanley[]

Frederic Stanley pursued new designs for Martindale's dust mask. This is reflected in several different patents filed by him during the period 1958 - 1964.

Stanley's 1958 model[]

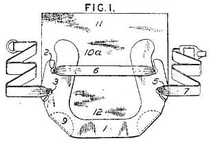

Patent drawing

This 1958 model was one of the first new designs to be patented by Stanley. It features a much more pronounced 'horseshoe' shape. If one looks closely at the patent image, there are two notches (labelled 2,3 on the patent) that had been cut into the face-plate. The bottom notches (labelled 3) appear to be the system by which the 1958 models' headband is attached. It would appear tension holds the headband in place.

The top notches (labelled 2) hold a flexible material (it is not stated exactly what it is, the patent merely states: 'non-metallic flexible deformable part'), this material splits the large faceplate recess into two regions - the users nose goes presumably on top and the users mouth sits beneath the flexible material.

The 1958 model features no side perforations - this is most likely because this design uses a much larger mouth hole than other Martindale models, thus making breathing resistance much less - thus obsoleting the perforations.

Additionally, this mask may have been an early attempt to create a cheaper product. By creating a much larger recess, less metal is used, thus decreasing production costs.

This models' filter pads are held in place by clips which are absent from the above patent photo. Additionally, the patent states the filter pads may be secured to a cardboard backing plate by staples.

Finally, this 1958 model patent was eventually accepted and the patent became active in the UK in May 1960.

Stanley's December 1962 model[]

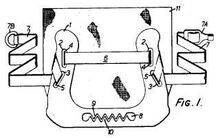

Patent drawing

On 11th December 1962, Stanley filed for another design. As one can see, the pronounced 'U' shape has disappeared and has been reverted back to the original design.

Very little appears to have changed with the only notable exception being the strap system. Instead of the original singular slot, this model features 3 parallel slots. Looking closely at the patent photo, the headband is passed from the rear to the front of the slot 8, back through slot 10, forward through slot 9 and again back through slot 8, providing an effective jamming action.

The patent for this mask was published in full and accepted on 1st January 1965.

Stanley's July 1963 model[]

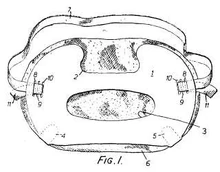

Patent drawing

On 30th July 1963, Stanley filed another patent for a new and updated Martindale mask design. This mask borrows much from the 1958 model design such as using a material to separate the nose recess from the mouth hole, and featuring a much larger recess.

The construction relating to the headband, however, changed. Instead of the 1958's design of notches, the July 1963 model used slots to thread the headband through. The patent also states the slots may have ribbed edging - probably done to decrease the chance of the headband fabric slipping around too much.

Looking at the bottom of the patent at labels 8,9,10 one can see a zig-zag shaped hole in the face-plate. This was a serrated pad retainer. The general idea of operation was for the user to push a section of the filter pad through, by doing so, the serrations on the zig-zag hole would catch and secure the pad to the face-plate. This removed the need for gripping tabs.

Perhaps most interesting about this masks overall construction was it was not made from metal, but plastic. Again, this was probably a cost-saving feature.

Martindale appeared to have high expectations for this mask - patents for this mask were filed in the USA, Belgium, Denmark, the Netherlands and Switzerland. All of these patents were filed on 24th July 1964, and became active in these various countries in or around 1967.

The UK patent for this mask was accepted and published in full on 24th November 1965.

Stanley's June 1964 model[]

Patent drawing

On 23rd June 1964, Stanley filed a patent for another mask design. This 1964 model is the most common of Stanley's variants and appears to be the final design choice in this particular series of Martindale masks.

This mask was probably used in conjunction with Stanley and Gerrish's improved filter pad.

For more information on this mask, refer to the above 'Mask overview' section.

Despite a couple different iterations by Stanley, the mask design reverted back to a similar design found in the original 1937 patent. There is no source indicating why, but it can be speculated that the masks with the large recess (1958 model, 1963 model) were too flimsy and the larger recess made the filtering pad move around too much, even in the presence of features to secure the pad.

Additionally, it has been speculated that the plastic version (July 1963) was not to consumer tastes; the apparent rarity of these particular models would imply not many were made. This may be because the plastic was not as malleable as the metal, thus achieved a less satisfactory fit on users' faces.

Refill Packs[]

December 1950 poster, showing a refill pack

Martindale Protection offered refill packs. In 1950, a refill pack consisted of 1 mask and 8 filtering pads at a cost of 4 shillings.