The T.35 is the most widespread Italian gas mask in history, serving for several decades in all sorts of scenarios and configurations, as either a civilian, territorial, military or industrial mask.

Although initially developed only as a territorial gas mask, it was quickly picked up by the REI (Regio Esercito Italiano, royal Italian Army) in 1935 for special duty in Ethiopia, and later it was used more and more, until in 1949 the M.31 and M.33 were completely ruled out of service in favour of the T.35, considered more practical and easier to maintain. After 1959, when the M59 was adopted, the T.35 kept being used for territorial use up until the '70s and training (both military and territorial) up until the '90s (according to a source possibly even into the '2000s).

It was also issued during the Spanish Civil War to the Nationalists and in Hungary to the Légoltalmi liga and other corps, in both cases the masks would still see use late after the Second World War in a variety of ways.

Mask overview[]

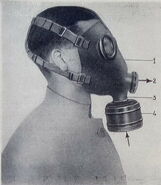

The mask is composed of the following parts:

The faceblank, made of moulded rubber, has the following parts attached to it:

- the housing for the exhale valve (outlet)

- the metal threaded piece that allows the filter to be screwed in and houses the inlet valve (inlet)

- the eyepieces

- the straps

The inlet valve allows filtered air in from the filter and does not allow exhaled air to go back out from the filter again. Said rubber valve is housed in the metal DIN threaded piece.

The exhale valve piece allows exhaled air to go outside and prevents poisoned air to get in. It's a single piece made of rubber, it's composed of a base rubber ring which serves as a sealing surface with the housing and the lid; connected to it is the tulip-style valve, composed of two discs: it opens under the light pressure of exhaling and closes hermetically under the negative pressure produced by the inhalation. It can be easily inspected and possibly replaced by unscrewing the lid of its housing.

The eyepieces are made of "Triplex" glass, which itself is composed of two glass layers and a thin sheet of cellulose. This kind of glass prevents poisoned air to get into the mask even after being hit, as only the outside layer of glass would be shattered and the other two layers would maintain the seal. The glasses are affixed to the mask through aluminium frames.

The elastic harness has the goal to keep the mask tightly onto the face. It is composed of 5 adjustable straps (a top one, two elastic temple ones and two elastic cheek ones) attached to the facepiece, they gather into a nape pad.

The anti-fogging lenses are kept tightly onto the lenses by metal inserts and, as the name implies, prevent fogging.

Sizes[]

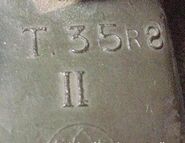

The T.35 comes in three sizes, with 1 (I) being the largest, 3 (III) being the smallest and 2 (II) being the average one. The size is marked on the left side of the mask with a roman number. Some civilian variations of the T.35 can be found in size 4 (either IV or IIII).

Markings[]

On the left side of the mask, besides the mask name and the size, there is the company's marking and sometimes a series of dots of varying meaning, with regular non-post-War T.35 following the same logic as M.31-33 masks: the dots indicated the year of production, following the logic of mask name's year (1935 in this case) + the number of dots (which could also not be there, meaning the mask was made in that exact year). Some other variants have dots after their name, but it's not known whether they follow a similar logic or a different one.

On the right of the mask, there is the kit's register number (lacking on industrial facepieces), on the inside, usually under the right eyepiece, there is the mould's number, and on the exhale valve there's the producer's logo. Post-War Pirelli masks also sport an ENPI logo on the right side and occasionally have an internal marking with the year of production.

The T.35 was produced by various companies for multiple years.

The main producers of the T.35 were:

- Pirelli

- I.A.C. (Industrie Articoli Caucciù, rubber items industries)

- Superga

- S.I.G.L.A. (Stabilimento Industria Gomma Lavorazione Affini, Industrial plant for processing rubber and related. It is also referred to as Sacic incorrectly, as it is a different company located in Belgium)

- Spasciani

Doctrine[]

Wearing the mask[]

Drill[]

Storage and decontamination[]

To preserve the mask, the manual recommends wetting the exhale valve with a solution of 30 % of glycerine and keeping the mask in a dark, dry and cool place, with the smallest temperature range possible.

Repairs[]

Variants[]

Pirelli license T.35 on the left and IAC license T.35 on the right

The T.35 was produced for numerous years by various companies (not to mention alterations done post-production), resulting in a myriad of variants and derivatives through which is often hard to navigate. This section will present all T.35 variants and all the masks that are not properly T.35s but close relatives.

First and foremost it's important to mention that two slightly faceblank designs fall under the T.35 designation:

- S.C.M. license n. 9 of 17th May 1935 released for IAC

- S.C.M. license n. 10 of 23rd November 1935 released for Pirelli

The main differences between these two designs are the shape of the "nose" section and the outline on the sides (see the picture for reference).

Also notable are the different inlet assemblies, with Pirelli types being less deep than IAC ones, and eyepiece frames, as Pirelli used smaller "teeth" than what IAC used.

Predecessors[]

These masks share the same setup as the T.35, with some minor differences. For a detailed description, check the individual articles.

- 30mm variant(s) of the T.33 or T.35. These masks are only seen in some ads and books, often improperly listed as T.35s. They sport a T.33/35 style facepiece with 50mm lenses, 30mm inlets and early outlet valve assemblies (see the early S.I.P. 3s for reference), suggesting that this design could have originated as early as the late '20s, but probably never saw widespread production in this configuration.

- T.32, the original Italian territorial gas mask. The exhale valve used is a VD 25, completely different compared to the T.35 one; the outlet valve cover differs by having larger holes and a central peg to hold the valve down. The faceblank has the socket for the thread pointing directly down.

- Pr.C.33, identical to the T.32, differing in markings.

- R.M.F., the predecessor of the R.M.F.35 and first user of the phonic device later used in various T.35 variants.

- T.33, the predecessor to the Pirelli license T.35 facepieces. The difference comes down to the outlet valve, which is identical, save for the slightly larger base rubber ring. The exhale valve cover, the straps and the faceblank can vary.

- P.C. 34, the predecessor to IAC's license T.35 facepieces. The difference is in the exhale valve cover, and possibly the exhale valve.

- T.34, the territorial version of the P.C. 34, only mentioned by some sources.

Pirelli license T.35 variants (interwar and early War)[]

The Pirelli license facepieces was the most successful of the two facepiece types, and over the course of the late '30s completely replaced the IAC license production. In general, the later a mask was made the worse the materials, with most having lighter metals used in the exhale valve cover. The companies producing under this license were the following:

- Pirelli, which owned the license. The masks produced were meant for both military/territorial use and industrial use (the latter didn't have a serial number, though some territorial ones were repurposed for industrial use). Later production masks tend to be slightly thinner.

- IAC, which switched to the Pirelli license in the late '30s. The masks of this type are always made with a single layer of rubber and use IAC-style inlets and eyepieces.

- Superga, the masks made by this company are identical to Pirelli ones, save for the marking and the rubber quality

- SIGLA, these masks were made with a rubber blend similar to the one used with IAC masks, and the eyepiece frames were IAC style, too.

- Spasciani, this company produced T.35s with two different rubber types, the earlier type masks were made with a pretty standard natural rubber blend, while later production suffered a sharp decline in quality. The later type masks can be distinguished by the colour, which tends to look browner and is often cracked.

- Pirelli (black), a rare Pirelli T.35 mask with black rubber and no additional marking (like SIR or Rs). Its use and age are unknown, it may be a T.35-SIR pre-series, a wartime industrial variant or an early Post-War production piece.

Pirelli masks can be found with non-standard repairs and irregular furniture and valves. These modifications were made in Spain during and after the Spanish Civil War, they are explored in detail in this section.

IAC license T.35 variants[]

Although completely replaced by the Pirelli license facepieces, the IAC license ones were produced in great numbers and were relatively as widespread in the early years. There are two properly-so-called IAC license T.35 variants: the earlier type was made with black rubber on the outside and khaki coloured on the inside, while the later ones were made exclusively of the khaki rubber.

The earlier type masks can be found with non-standard repairs and irregular furniture and valves. These modifications were made in Spain during and after the Spanish Civil War, they are explored in detail in this section.

Special rubber T.35 variants[]

During the Second World War, the severe lack of natural rubber impaired the production of the regular variants of the T.35, and as a result, the production shifted to the use of synthetic rubber blends and possibly reclaimed rubber.

The most used blend was Buna-S (currently known as Styrene-butadiene rubber), which is the type of Buna closer to natural rubber in terms of mechanical properties (in some cases, the rubber was partially depolymerised during production to better mimic natural rubber). The similarity to natural rubber was a necessity in order to be able to use the same moulds.

Buna-S could be produced with two procedures, which differed in the way through which acetaldehyde was obtained: with the method patented by Buna Werker, hard coal was distilled to obtain the acetaldehyde, while the Italian method used ethyl alcohol obtained from beets. Rubber produced with the former method was produced in Terni and also imported; the rubber produced with the latter method, colloquially referred to as "Cauccital", was instead the outcome of a study started by Pirelli and IRI in 1937 (based on the studies of Ivan Ivanovich Ostromyslenskij but with new ideas and technologies to improve the process) and was entirely produced in Italy.

The use of Buna-N for facepieces, even though superior to Buna-S in mechanical properties, is very unlikely due to the fact that it's harder to work with, but it's possible it could have been used for hoses on rebreathers and optical masks, which are not the focus of the article.

Although mostly used for military and territorial use, Pirelli offered these special rubbered masks for industrial use since the '40s (possibly even during the War) up until the '50s, when newer variants would start being produced.

T.35R[]

The T.35R was a variant of the regular T.35 that differed only in the use of a double layer of rubber, with Buna-S rubber on the inside and a lighter-toned one (likely either natural rubber or reclaimed rubber) on the outside. The companies that produced this variant were Pirelli (grey/walnut brown), IAC (beige), SIGLA (dark brown) and possibly Superga.

T.35Rs[]

The T.35Rs were composed of a double layer of rubber, internally Buna-S and light to dark grey rubber (likely either natural rubber or reclaimed rubber) on the outside. The nape pad was simplified, and the pad properly said was made of thick canvas. The companies producing this variant were Pirelli, IAC, Superga and SIGLA.

T.35-SIR[]

This variant of the T.35, exclusively produced by Pirelli, was moulded using only Buna-S rubber (most likely "Cauccital"), and had simplified furniture, those being the previously mentioned simplified straps and an exhale valve cover made with lighter metals.

Civilian variants[]

P.C. 35[]

popolazione civile 35,civilian population 35

main article: P.C. 35

The P.C. 35 was IAC's civilian use of their T.35 facepiece license. It differed from the territorial/military ones by having only by the slightly different pattern of nape pad and by having different markings.

Pir. 35[]

Pirelli 35

main article: Pir. 35

The Pir. 35 was Pirelli's civilian T.35 variant. It was virtually identical to its military counterpart, save for markings. It came with either a dedicated T.35-style bag or a metal tube carrier, depending on the buyer's needs.

R.S. 37[]

Riccardo Spasciani 37

main article: R.S. 37

The R.S. 37 was Spasciani's civilian T.35 variant. It didn't differ from the military model, save for the markings. A post-War variant was made for industrial use.

P.C. 40 (wartime-production)[]

popolazione civile 40,civilian population 40

main article: P.C. 40

The P.C. 40 was the cheapest variant of the T.35 ever devised, and it was issued for a small price and in certain contexts for free to the civilian population in case of a real threat of chemical attacks. It had thinner rubber, cellulose glasses and exclusively aluminium parts. A post-War variant was made for industrial use. It's possible that the wartime variant was used in industries as well.

Phonic variants[]

F.T.35[]

Fonica Territoriale 35, Territorial phonic 35

main article: F.T.35

This variant of the Pirelli license facepiece was moulded with little to no difference in the rubber mask, it had a phonic device in front of the exhale valve to enhance the voice of the user and was provided with a Tissot system to prevent fogging. These kinds of masks were used by the Navy. F.T.35 masks were produced by Pirelli, Spasciani and SIGLA. There were two types of "trumpets" used, a larger one for early Pirelli production and a smaller one for all the other masks. IAC produced a similar variant, mentioned in the next section.

T.35.F.[]

Territoriale 35 Fonica , Territorial 35 phonic

main article: T.35.F.

The T.35F. was IAC's take on the phonic concept, which unlike Pirelli's design was based on a unique mould. It sported a phonic device in front of the exhale valve and a tissot system. There are two variants, an earlier model made with IAC's signature double layer rubber (black outside and beige inside), and a later model made of beige rubber only.

P.C.35.F.[]

Popolazione civile 35 Fonica , Territorial 35 phonic

main article: P.C.35.F. (article pending due to lack of sources)

The P.C.35.F. is the non-military equivalent of the T.35.F., differing only by the marking on the left and the lack of a serial number on the right. Its use is unknown, possibly industrial, civilian, or both, perhaps outside Italy, too.

R.M.F.35[]

Regia Marina Fonica 35, royal navy phonic 35

main article: R.M.F.35

The R.M.F.35 was Pirelli's take on the R.M.F. with a facepiece based on the Pirelli license T.35, much like the F.T.35. Earlier masks are found with the larger "trumpet", while later types have a smaller one. Some masks were issued with a hose and a large filter while others were issued with kits identical to F.T.35 ones (the facepieces in each of those kits would have to have a specific inlet thread, specifically a male 43mm thread for large kits and 40mm female DIN for small kits).

L.F. 40[]

Lanciafiamme 40,flamethrower 40

main article: L.F. 40

The L.F. 40 was an F.T. 35 variant designed for use with flamethrower units. It was coated in asbestos to insulate the user from the heat and provided with hooks to attach a hood.

Post-War production[]

After the end of the War, the T.35 was still widely issued and many masks were used as surplus by industries. But yet, new T.35 variants were made and used, mostly by industries and non-military corps.

Post-War Pirelli T.35 masks[]

After the war, T.35 masks made by Pirelli were manufactured with a new kind of blue-grey rubber and were mostly used by industries and firefighters, but also other territorial organizations and the Army. They all had small rubber studs around the eyepieces that served the purpose of keeping anti-fogging lenses adherent to the glass. The external markings always included Pirelli's new symbol (adopted in 1946) and the ENPI logo. The markings, inlet pieces and rubber shade varied slightly, but the biggest difference in production was the strap systems.

Transitional version[]

sample text

First version[]

The first type of post-War Pirelli T.35 production used the standard strap system used with pre-War T.35 masks. The earliest types used rubber that was more grey than blue, an inlet thread with a single stud going across it and valves made of the same blue rubber. Later models would have rubber with a bluer shade, and sometimes an inlet piece with a cross formation, like the one used with the M59.

Second version[]

The second type of the post-War Pirelli T.35 used rubber straps and a double hook system instead of the regular one seen in the previous versions. It always included the cross-type inlet piece and a date marking inside the faceblank.

P.C. 40 (Post-War)[]

popolazione civile 40,civilian population 40

main article: P.C. 40

During the '50s and '60s, the P.C. 40 started being produced to a higher standard for industrial purposes, while still keeping the designation used for civilian ones (this may imply that at some point they were offered as civilian/civil protection masks). There are two variants, one with grey rubber, a single-stud inlet and a harness identical to the wartime one, while the other one has blue rubber, a cross-type inlet and a T.35-style head harness.

P.C. 50[]

popolazione civile 50,civilian population 50

main article: P.C. 50

The P.C. 50 was an improved version of the post-War P.C. 40, with an integral Tissot system, meant for the same uses and produced at around the same time. There were two main variants, an earlier type with grey rubber with a hint of blue, an inlet piece with a single stud and a dedicated strap system made of rubber with the top strap made rigid. The later variant was made with bluer rubber, a cross-type inlet piece and a rubber harness with a double hook system. Some masks may have been used by civilians/civil protection.

RS-37 (Post-War)[]

Riccardo Spasciani 37

main article: RS-37

After the end of the war, Spasciani made an updated version of the R.S. 37 with rubber straps, exclusively intended for industrial use.

Hooded variants[]

S.I.P. 6 with T.35 facepiece[]

main article: S.I.P. 6

The S.I.P. 6 was a series of Pirelli masks that had a specific hood type attached to them, along with other modifications. The late variant of the S.I.P. 6 was made using a T.35, and it was made with either white or blue rubber. The mask sported a hook system with rubber straps outside its rubberized hood, which could be covered with "resivite" material if requested. This mask was used by industries when there was a risk of corrosive splashes.

Optical variants[]

During the late '30s, Spasciani experimented with optical prototypes of the T.35, possibly as a competitor for the mask that would become the O.39. The company holds all existing pictures and surviving examples (some with 5 straps and some with 7).

Copies and foreign production[]

Spanish T.35 copies[]

Main article: Spanish T.35 copies

After the battle of Guadalajara in March 1937, the Republican Army captured hundreds of Italian gas masks. Some of the captured ones were also sent to Bilbao and in Catalonia to develop copies, and in a few months, a great number of copies were made, with varying quality. The thread chosen for the inlet was 42mm, to use Czech filters.

Ajax F2 misconception (not actually a T.35 copy!)[]

Main article: T.33 section on the Ajax F2

Contrary to popular belief, the Ajax F2 is not a T.35 copy, but instead it's a copy of the earlier T.33. The difference stems from the harness and the exhale valve assembly.

Kits[]

Territorial and military kits[]

Although initially meant for territorial use, most of the early kits were issued to the Army to some degree, with some later ones being exclusively for military use.

Standard territorial-military kits[]

Note that the names of the kits in this subsection are merely there to ease the understanding of the reader, as historically they weren't distinguished.

Standard early kits[]

From 1935 to around 1937, T.35s would be issued with this type of kit:

- Either a tin carrier or a canvas bag, with the former being exclusive to territorial use

- T.35 facepiece, made by either Pirelli or IAC

- T.35 filter

- At least a set of anti-fogging lenses

The U.N.P.A. kits are almost identical, with the only difference being the markings and the colour of the filter for Pirelli kits. All Spanish T.35s were first issued with this type of kit (always with a canvas bag), a lot went through the recovery process and a lot were refurbished.

Standard complete kits[]

These types of kits were generally issued mostly around 1939 and 1940. When unopened, both the filter and the mask were wrapped in paper, and the tab that closes the bag was tied with a string that had the company's seal attached.

The kits included the following:

- Canvas bag, with a size stamp occasionally (some Pirelli kits could be issued with a tin carrier instead)

- T.35 facepiece, made by Pirelli, IAC or Spasciani

- T.35 filter

- User manual

- Anti-fogging lenses and spare exhale valve (Spasciani kits had their spare exhale valve and anti-fogging lenses in the same small box)

Standard late kits[]

These kits were made and issued broadly from 1938 up to 1943, mostly to the Army in the later years.

- Canvas bag, with a size stamp occasionally, or a cardboard tube (only used with some SIGLA T.35R facepieces)

- T.35 facepiece, made by Pirelli, IAC, SIGLA and Superga (early on with natural rubber facepieces, while later on mostly with special rubber masks)

- T.35 filter, or in rare occasions an SCM-41

- At least a set of anti-fogging lenses and rarely a spare exhale valve (Spasciani kits had their spare exhale valve and anti-fogging lenses in the same small box)

U.N.P.A. kits[]

The U.N.P.A. was issued with a unique kit almost identical to standard early kits, with the differences being that the facepieces were marked in a unique way and that the T.35 filters could have been either orange or the regular brown. The carrier used was either the metal one for Pirelli masks, the metal one for IAC ones or the regular canvas bag, again for IAC masks.

[]

The Navy-issued T.35s were used exclusively for Navy duty on land: if someone serving from the land was to be moved to a ship, his T.35 kit would be withdrawn (an R.M. kit would be issued on-board). The kit consisted of the following:

- A standard canvas bag for early kits, or, for later kits, one with a small transparent pocket that allowed a tag to be put in, which showed the name, issue number and unit of the owner of the mask

- T.35 facepiece, made by Pirelli, IAC, SIGLA or Spasciani

- T.35 filter with a paper sheet attached to it where the issue number, unit the mask was issued to and a brief paragraph explaining when to change kit

- At least a set of anti-fogging lenses

M.42 kits[]

This wartime kit was an updated version of the standard late kits which would improve the protective capabilities with a number of changes, but, due to severe shortages of material during the War, a lot of the times most of the kit wouldn't be present.

The complete kit would consist of the following:

- M.42 bag, an updated standard bag that had 2 extra pockets covered by an elongated flap. Some of these bags sported a large pocket in the bag for keeping a protective sheet

- Special rubber T.35 facepiece, made by Pirelli, IAC, SIGLA or Superga

- M.42 filter (a lot of the times a T.35 filter would be present instead, regardless of the lower protective capabilities. It's possible some could have been issued with an SCM-41 filter, too)

- At least a set of anti-fogging lenses

- A spare exhale valve (rarely present)

- PAI M.41 anti-blister kit (rarely present)

- A protective sheet either imported from Germany or made in Italy (almost never present, by the 23rd of May 1943 only 500 thousand were available, with 400 thousand being imported, compared to the 3 and a half million total masks available to the army)

Note that even though a lot of these kits are found without most of these accessories, it's likely that in some cases some accessories were lost or disposed of because of Post-War use or general mishandling. Still, a lot of incomplete kits are indeed original.

Post-War kits[]

After the war, a great number of T.35s were available in all sorts of configurations, and with the making of the

- Canvas bag, either the regular type of the M.42, with a preference for the latter especially in the Army

- Pre-1945 T.35 facepiece, of any type that was sufficiently suited for issue (both natural rubber and special rubbers were used); alternatively, some Post-War Pirelli T.35s were used

- Usually either T.35, M.42 or SCM-41 filters, for actual use early on but only for training afterwards. Some post-1958 kits may feature T.35/58 or M.58 filters

- At least one set of anti-fogging lenses

Irregular territorial kits[]

Occasionally some standard T.35 kits can be found with civilian filters, most of the time Pir. 35s. This can be due to a variety of reasons:

- Most commonly, those are simple collectors' mixups, therefore not historically relevant

- Filters that were damaged were sometimes replaced with commercially available ones (only for smaller territorial corps and other civilian organizations that may have used T.35s)

- Some of the masks that were recycled as industrial masks were used with civilian filters

Civilian kits[]

The T.35 was not normally offered to civilians commercially, as they could purchase the dedicated civilian variants with dedicated kits. These kits are described in detail in each variant's page and can be seen in the dedicated sections.

Industrial kits[]

This section includes only kits that were purchased directly for industrial use, but it's important to acknowledge the fact that any civilian, territorial or military kit, especially after the end of the War, could have been recycled for industrial use.

Pirelli kits[]

Industrial T.35 masks were issued with a range of different kits, which depended on the customer's necessities. The facepieces used were initially only natural rubber ones, but in the '40s (possibly even during the War) and early '50s, special rubber variants would be offered. Starting from the '50s up until the early '70s blue/grey rubbered T.35s would be produced.

Post-War-made P.C. 40s (it's likely that wartime P.C.40s were used industrially as well) and P.C. 50s were also offered with the same kits, since they were thinner they were marketed as more comfortable and were actively recommended for more demanding work.

If the mask was to be used with a small filter (Dirin), the kit would consist of these:

- Mask

- Filter

- Tube carrier for earlier kits, especially pre-War ones, while later on the canvas bag was offered too

- Either anti-fogging soap for very early kits, or alternatively anti-fogging lenses

- Occasionally a spare exhale valve

When the mask was used with a large filter (Tubin or Turnivercio) the kit would be like this:

- Mask

- Filter

- Hose, threaded on one end to connect to the mask

- Cage carrier for the filter

- Metal box to store the kit

- Either anti-fogging soap for very early kits, or alternatively anti-fogging lenses

- Occasionally a spare exhale valve

The T.35 could also be issued with a special hose to attach to a fresh air breathing apparatus.

Spasciani kits[]

main article: RS-37

The only Spasciani T.35 variant that was sold for industrial use was the RS-37, which was produced after the War. The kits included the mask, an industrial filter, some method of defogging and possibly a bag.

Fire brigade kits[]

The pre-War fire brigade T.35 kits were usually standard territorial-military kits with their bag marked "V.V.F.". After the War, the mask used were mostly Post-War production T.35s sporting Dirin 600U universal filters, with canvas bags and a set of anti-fogging lenses.

Spanish kits[]

This section explores both wartime kits and post-War use.

Original kits (Modelo L and Italian volunteering soldier's T.35s)[]

During the Spanish Civil War, a great number of Italian gas masks, and in particular T.35s, were imported into the country. The designation chosen by the Nationalists was "Modelo L", a name that would later change to "L.T.35" after the war. The kits that were imported were either IAC or Pirelli early kits. To this day, few kits remained in their original state, as a lot were captured and modified by the Republicans and most were recovered after the War.

Republican kits[]

The Republicans captured and re-issued numerous T.35s during the War, especially after the battle of Guadalajara in 1937. The kits that were re-issued were often identical to the standard kits, but occasionally repairs to the inlet or outlet assemblies were made, which consisted in either replacing a valve or a whole assembly, sometimes with parts that were not firm-consistent with the rest of the facepiece (this was due to the different availabilities in different warehouses); in the case that a whole assembly was replaced, it would be taped back using tape, wire, red string and then tape again, covered in blue paint afterwards. It's unclear whether the white tape used over the seams between the faceblank and the straps was done during the War or not. Most republican kits were recovered after the War, and additional modifications could have been done.

Most of the modifications to the facepieces that are mentioned in the recovery section have been probably made during the war by the republican side.

L.T.35 kits (following the Spanish Civil War)[]

The name "L.T.35" was the post-War designation assigned to those T.35 kits that were used by the Spanish Army. The kits and facepieces that fall under this designation are numerous, as there was great variability in the sorts of spare parts used to repair said facepieces or to replenish their kits.

An L.T.35 kit was composed of the following:

- Facepiece, which can have anywhere from no modifications to most parts having been replaced with either Italian or Spanish parts. More detail in the following sections.

- The filters used were various; the original T.35 filter with a "recovery" label, or any 40mm German filter used at the time, in which case the mask would be provided with a gasket (CMP post-War filter, cmp pre, dagsa post and pre, n-24, list of other filters)

- Carrier, initially the standard Italian bag, but later on a Spanish copy made in green with a buckle, and, in later instances especially, a repainted metal carrier like the ones issued with German-license masks

- At least a set of anti-fogging lenses, sometimes present only when issued.

The inlet valve (35mm wide) could be replaced with any T.35 inlet valve, regardless of the producer, but also with an inlet valve from any Victoria, Dagsa or N.24 (all three 33mm wide), L.M.33 (35mm wide), Fatra (36mm wide), or in rare cases CMP masks (with the latter being not recommended in manuals due to the extra breathing resistance caused by the excessive diametre, 37mm).

The harness can sometimes present straps with material different from the original fabric: these types of repairs were made when the non-elastic part of a strap was thorn, otherwise the entire harness was replaced.

The kits mentioned in the next subsections are the most common configurations, but any other kit with a mix of those characteristics may be accurate, due to the fact that the masks could be repaired in a number of ways depending on the availability at the time and at the warehouse.

Recovery kits[]

After the end of the Spanish Civil War, the government set out to gather all of the various gas equipment issued by both sides, in an effort to re-issue said equipment in a standardized way. A lot of T.35 kits went through this recovery process, and after that, some were refurbished and used in the Army. The filters were labelled with a paper that stated the recovery origin of the filter.

These facepieces can sometimes present multiple modifications, some of which could have happened during the War:

- Inlet piece replaced with a piece from a different firm (Pirelli with IAC and vice versa)

- Inlet valve replaced usually just with one from a different firm (Pirelli with IAC and vice versa)

- Outlet valve replaced with a piece from a different firm or from an M.31-33

- Different wiring and tape for the connections with the inlet and outlet, done when repaired by the Republicans during the war

- White tape used over the seams between the faceblank and the straps, this modification is possibly Republican tooInside of an IAC sample. Note the white parts, which are signs of a repair done to the strap system's attachment points

Spanish refurbished variants[]

In the early '50s, the "La Marañosa" firm refurbished a great number of Recovered T.35 masks from the Spanish Civil War to have them issued to the Spanish Army.

The masks and especially their kit were subject to major changes:

The previous kit was completely disposed of, save for the anti-fogging lenses. In place of it, the mask was issued with a CMP post-War filter filter and a dedicated bag, similar to the regular T.35 one but green and closed with a buckle.

The mask itself had the housings of the inlet and outlet valve resealed with special clamps instead of wire and tape like before; the inlet had a rubber ring added to it to seal with CMP filters, which didn't have external rubber rings like T.35 filters. The furniture of the masks was painted with the Spanish Army's standard green to signify its use with said army and cover the Italian paint and the tape that covers the seams between the faceblank and the straps was replaced. Other changes could be present, too: the inlet valve is often not the standard one (either from a different company or a totally different mask, as mentioned in the second last paragraph of this section), the exhale valve was occasionally replaced another T.35's or an L.M.33 one, and in general some Pirelli facepieces can have IAC furniture or vice versa.

In the early '60s, the "La Marañosa" firm again refurbished T.35 masks, this time the carrier used was a repainted metal container, much like other German-derivative masks of the Spanish Civil War. The facepieces for these later kits were most of the time L.T.35-ABs.

Standard refurbished facepieces[]

Although most modifications done to the L.T.35 facepieces wouldn't change the designation, there were some that would because they'd change core parts of the mask with Spanish-made parts, as described in the following subsections.

L.T.35-A[]

also L.T-A.

On this variant, the original Italian exhale valve assembly has been replaced with a more rigid one, to make the denting of this piece more unlikely. In this type of newly made assembly, there is no internal guard between the user and the valve, as it was deemed expensive and unnecessary. Furthermore, a metal disc was inserted over the base of the valve where the cap would usually press the rubber. This was done in order to add further rigidity to the valve assembly.

L.T.35-B[]

also L.T-B.

On this variant, the original Italian inlet valve assembly has been replaced with a more resistant one that was less likely to dent, either made of cast metal or plastic, similar in shape to the one removed but with 4 holes under the inlet valve to let air in.

L.T.35-AB[]

also L.T-AB.

As the name implies, this variant has had both the inlet and outlet assembly replaced with Spanish-made parts, mentioned in the two sections above.

Hungarian kits[]

In 1938 a number of Italian masks were imported in Hungary, among which most were T.35s. Though they were imported with a specific kit, a lot were repurposed with different uses.

Mg. gázálarc kit[]

The Mg. gázálarc kit didn't differ much from the Italian early Pirelli ones, but there were some differences. It consisted of the following:

- Mask (usually a T.35 but occasionally a T.33). They had a series of markings depending on the user (see the gallery)

- Filter, either a T.35 or a Dirzepest (if there was no dedicated filter available, a rubber gasket was added to the thread to be able to mount a Hungarian 34M filter)

- Canvas bag, also marked accordingly. Some times the mask could be sold with a carboard carrier

- At least a set of anti-fogging lenses

The cost for a kit was 23 Pengő with bag or 18,50 Pengő with a cardboard carrier.

Hungarian industrial kits[]

After the end of the War, part of the T.35 surplus in Hungary was put to use in the industries. Normally the masks had a rubber gasket to be able to seal with Hungarian industrial filters. Kits including the mask had the filter either attached directly to the facepiece or attached through a hose.

Rebreather use[]

Some of the surplus T.35s ended up being used with rebreathers for mine rescue (with either Dräger KG rebreather series or Degea Audos MR series rebreathers). The mask would have had to be modified in order to work with these apparatuses:

- The exhale valve would have had to be removed and replaced with a blanking disc

- The inlet valve would have to be removed, as air would cycle both in and out through the inlet.

Service life[]

Development

During the late '20s-early '30s the Italian Army was seeking renovation in its chemical protection equipment. The first mask adopted after the Small Box Respirator was the Penna in 1928, which was widely adopted in the Army. Because of its various flaws, after 2 years the Army was seeking renovation again. Furthermore, there was a push to prepare the civilian population for possible chemical attacks.

These factors led to the creation of 3 classes of masks, with different price ranges and purposes:

- The M.31 was adopted as the main military mask (maschera militare o maschera campale, military mask or field mask, designated as "C" type), and its price was higher than 80 lire (Italy's currency at the time) per piece, which was a lot compared to the other two classes, but that kind of mask could protect the wearer for a very long time due to the larger filter connected through a hose.

- The P.C. 30 (popolazione civile, civilian population, designated as "P.C." type)was adopted as the main civilian mask, with its price being 30 to 40 lire per piece. Its duration was much shorter, as the filter was smaller and attached directly to the mask, but for civilian passive use it was sufficient.

- The T.32 (territoriale, territorial, designated as "T" type) was developed as an intermediate solution, cheaper than the military class of masks but sturdier than the civilian mask, made for use with trained non-combatant personnel, from which derives its designation as a "maschera territoriale" (territorial mask).

The T.32 saw some use but it was later dropped for newer models. During the Pr.C.33 was adopted, and it was used in the same manner as the T.32, but mostly for propaganda purposes.

During the following years, the two main companies selling gas masks to the Army (Pirelli and IAC) provided two similar designs for a new territorial/civilian mask with a chin-mounted filter, respectively the T.33 and the P.C. 34/T.34. These designs would later be refined, and since both were fit for their purpose, they would be adopted in 1935 under the same designation, T.35.

Adoption[]

This new territorial mask, lighter than a military mask and more robust than a civilian one, was fit for a lot of purposes, and because of that, it was widely issued to most territorial forces, replacing pretty much all respirators used before. In some instances, some civilian variants of the T.35 and other respirators approved by the S.C.M. were used, mostly those suited for active civilian duty.

The Army initially issued T.35s as second-line masks due to the lower cost and duration, but almost instantly they'd be used in other scenarios like in Ethiopia, as the weight and bulk of a full military respirator were deemed excessive and gas attacks from the enemy were deemed improbable or minute in scale at most. Over the following years, the army would adopt the T.35 for all of its colonies and for a big chunk of the army, especially those that needed lighter equipment (paratroopers and bersaglieri), eventually replacing completely the M.31-33 in 1949.

The Navy at the time had 3 masks issued, the R.M.2 and R.M.3 were the regular types and the R.M.F. was the phonic type. In 1935, they adopted 4 masks for different duties:

- The T.35 was adopted in the Navy exclusively for terrestrial duty with a dedicated kit.

- The F.T.35 and T.35.F. were also adopted for exclusively terrestrial duty, with the difference being that they featured phonic devices to ease communication.

- The R.M.F.35 was adopted as a properly naval phonic mask much like the R.M.F.. Some of the later kits would sport terrestrial duty kits with a 40mm DIN connector.

1937, night-time air-raid protection training[]

1942, UNPA training[]

Various other instances of the T.35 being used[]

Conflicts[]

Ethiopian War[]

The first conflict the mask saw use in was the Second Italo-Ethiopian War, in which, as previously mentioned, the T.35 was preferred to the M.31-33 as it was less of a hindrance and because gas attacks from the enemy were not expected to be grand. Gas has been used by the Italian side, but it's unlikely that the T.35 were actually used.

Even though the T.35 was lighter, less bulky and with lower breathing resistance than the military mask, the troops still preferred the latter due to the pain the former caused to the forehead and temples caused by the weight of the filter.

Spanish Civil War[]

The first European conflict this mask saw use in the Spanish Civil War. During this conflict, there was a strongly felt fear for gas attacks from both sides, and because of that, there was a rush to get the soldiers ready against this threat. The nationalist faction received aid from Germany and Italy, which supplied respectively 50.692 and 318.908 gas masks. The Italian masks gifted this way were mostly if not completely T.35s (which were adopted under the designation "Modelo L"). When Italian volunteering soldiers entered the battlefield, they were issued with T.35s, M.31-33s and Pennas.

Author's note: it's unclear whether the M.31-33s and Pennas that entered the country came all from the volunteering soldiers or partially from the 318.908 gas masks imported to be used by the Nationalists.

After the battle of Guadalajara in March 1937, the Republican Army captured hundreds of Italian gas masks, which would be issued against the nationalists during the rest of the war. Some of the captured T.35s and M.31-33s were also sent to Bilbao and Catalonia to develop a copy: these copies were produced in Bilbao in Euskadi and Villanueva y Geltrú in Catalonia (unknown numbers). The captured T.35s that had damage done to them were repaired with spare parts (often not firm-consistent, meaning Pirelli masks could get IAC parts and vice versa), sometimes they had rewired inlets and outlets with blue tape, and the seams between the faceblank and the straps were covered by extra tape, white in colour (the latter might have happened later on).

Spanish use after the Spanish Civil War[]

After the end of the Spanish Civil War, the government set out to gather all of the various gas equipment issued by both sides, in an effort to re-issue said equipment in a standardized way.

A lot of T.35 kits went through a recovery process and they started being issued designated as "L.T.35". A lot of different modifications were done, described in detail in the dedicated section. They would get replaced by the M2-73 in the '70s, along with all the other masks used at the time.

Second World War[]

At the beginning of the Second World War, the Italian Army was underprepared for an all-out war, due to the heavy expenditures from the previous two Wars (in Ethiopia and Spain), and as a consequence a lot of the equipment was outdated and there weren't enough funds for proper updates. The officially adopted masks were the M.31 and M.33, but the T.35 became the most issued mask pretty quickly, being brought to every battlefield and being subject to the improvements mentioned in the next paragraphs.

In the field of gas warfare, the biggest issue at the beginning of the War was the possibility that the British would use hydrogen arsenide and hydrogen cyanide, substances that greatly reduced the duration of the current-issue filter, as they were not filtered efficiently. The initial solution was to procure 100.000 SCM-41 filters from Germany, which were based on the Fe37RTp and Fe41 but provided with a gasket to seal with Italian masks. Meanwhile, a native solution would be developed, the M.42, which would start being produced in early 1943. Even though the T.35 filter wasn't sufficiently protective anymore, it would still be used and produced alongside the newer filters.

Another serious issue was the lack of natural rubber imports: since before the War, there was a push for local production of rubber so that the country would be independent in that regard. Initially, the ministry of Industry sponsored two different projects, which both involved the IRI and Pirelli; one involved the guayule plant, an alternative source for natural latex originating from the United States and grown in southern Italy, while the other project was about the production of Buna-S with local materials and a novel procedure. The former didn't see much success, while the latter became the main source of rubber used in gas masks during the War: all the special rubber T.35 variants as well as O.41s and some Rebreathers used Cauccital (Italian-made Buna-S) for their facepieces, some partially, while others completely.

Even though the filter problem was somewhat fixed and the production of synthetic rubber aided the production of masks massively, the armed forces were still utterly unprepared for all-out chemical warfare. By the 23rd of May 1943, out of 5 and a half million masks needed to fully equip the army, only about 3 and a half were available, with most of those not being equipped with the newer, more efficient filters. Gas masks for animals were not available, protective clothing and protective sheets were also severely lacking. The civilian population was also not fully prepared, only part of the endangered citizens purchased a mask, but a lot of the unsold masks were distributed to cities, ready to be given out in case of need. The only group fully prepared were all the corps that were required by law to own gas masks.

In conclusion, the problem of gas warfare was insurmountable due to the general lack of resources and therefore the Army was advised not to start using gas, but in case that type of warfare was started by the Allies, part of the Army and the civilian population could be fully protected. Gas was never used in the end during the War, so the problem never presented itself.

Post-War military and territorial corps' use[]

After the end of the War, the Army still issued both T.35 and M.31-33 masks, but as soon as 1949 the latter was ruled out of service due to complexity in maintenance. During the following years, the T.35 was the main military respirator, alongside a small number of imported M9A1 masks. In 1959 the Army adopted the M59, which slowly replaced the T.35, which was still used for minor roles and later on only for training. The territorial corps that used the T.35 used it for longer than the Army, but also slowly replaced it with alternatives like the M59 for the red cross or commercial respirators like the C.60 (this one in particular for firefighters). The latest the T.35 was seen being used by any institution for anything different than training was during the late '70s. Some sources claim it was used for training until shortly after the adoption of the M90 (according to a source possibly even into the '2000s).

Passive civilian use and further development[]

Though the T.35 wasn't sold directly to civilians, the civilian variants approved by the S.C.M. could be sold instead: initially only the Pir. 35 and the P.C. 35 from respectively Pirelli and IAC, but later on Spasciani offered its own variant too, the R.S. 37 (a licensed copy of the Pirelli pattern masks).

During 1940 and 1941, a new civilian variant of the T.35, the P.C. 40 started being sold in place of all other S.C.M. licensed masks, in an effort to simplify logistics and standardise. It was much cheaper to produce than the regular type, as it had thinner rubber, cellulose lenses and exclusively aluminium furniture. It was produced by Pirelli, SIGLA and Superga in two types of standardised kits, either with a cardboard box or a cloth bag.

It's important to mention the Post-War P.C. 40s and P.C. 50s: although they use a civilian designation, they have only been seen in Pirelli catalogues being sold as industrial masks, so unless proven otherwise it's unlike that they were ever meant for any other role.

Industrial use[]

The T.35 and its variants, much like all the other niches it occupied, permeated the Italian industrial scene for several decades. A number of T.35 variants have been sold as industrial masks from the late '30s up to the late '70s, but a lot of masks, especially in the late '40s and early '50s, were wartime surplus (be it military, civilian or territorial) that made its way to the companies that used it.

The kits varied a lot, with the most frequent being a facepiece with a selected filter specific for the gas the worker would get exposed to. Surplus masks would usually come with their original filters, which usually still worked well enough for certain threats. With the years advancing, T.35s have been slowly ruled out of industrial use in favour of more modern options, with the last kits being sold around the late '70s (it's safe to assume though that they have been used to a small degree even one or two decades afterwards, possibly even into the '2000s).

Hungarian use[]

After the Bled agreement of 22 August 1938 Italy gifted some masks to Hungary; the first masks were imported by Mercur Műszaki és Vegyipari Rt. but later this was done by Légoltalmi Kft. (Air defence Co.) as early as 1938, alongside with other Italian Pirelli masks like the T.33 and the S.I.P. 3, with either T.35 and Dirzepest filters.

On the 16th of January 1939, the T.35 and T.33 with T.35 and Dirzepest filters went into service as the Mg. gázálarc (Hungarian: Gumi munkgagázálarc , Rubber work gas mask), for the Ruthenians in Hungarian occupied Transcarpathia it was called Рз. противогазъ ("Rz. protivogaz"). These kits were issued with the Légoltalmi liga (the predecessor of Polgári védelem, Civil Defence), the Magyar Királyi Posta (Royal Hungarian Post) and generally to civilians and organizations that would be vulnerable to a gas attack. The price was the same as the M. gázálarc: 23 Pengő with a bag or 18,50 Pengő with a cardboard carrier.

At some point IAC made masks were imported too, but the circumstances of this import are unknown.

After the war, the masks were used in industries and a lot of masks were converted for use with rebreathers, for mine rescue (with Dräger KG rebreather series and Degea Audos MR series).

Users[]

Italy[]

Regio Esercito Italiano aka REI (Italian royal army). First adopted in 1935, the T.35 was used until the dissolution of the REI

Regio Esercito Italiano aka REI (Italian royal army). First adopted in 1935, the T.35 was used until the dissolution of the REI

Esercito Nazionale Repubblicano (Italian RSI army). Issued the T.35 since its formation and until its dissolution

Esercito Nazionale Repubblicano (Italian RSI army). Issued the T.35 since its formation and until its dissolution

Esercito Italiano (Italian army). The T.35 was used as the main respirator until the adoption of the M59. It used the T.35 for training for a long time afterwards, possibly even into the '2000s

Esercito Italiano (Italian army). The T.35 was used as the main respirator until the adoption of the M59. It used the T.35 for training for a long time afterwards, possibly even into the '2000s

Guardia di Finanza (Italian finance military police). Like the Carabinieri, it issued the T.35 until the '70s or possibly later

Guardia di Finanza (Italian finance military police). Like the Carabinieri, it issued the T.35 until the '70s or possibly later

UNPA aka Unione Nazionale Protezione Antiaerea(national union for air-raids defence, fascist). It used the T.35 in its dedicated UNPA variant but also in the regular version and in the other civilian versions

UNPA aka Unione Nazionale Protezione Antiaerea(national union for air-raids defence, fascist). It used the T.35 in its dedicated UNPA variant but also in the regular version and in the other civilian versions

Italian civil defence (post-War). The T.35 was issued with territorial kits until the '70s or possibly later. Civilian variants were issued this way too

Italian civil defence (post-War). The T.35 was issued with territorial kits until the '70s or possibly later. Civilian variants were issued this way too

Fire Brigade. Before the war, T.35s issued to this corp had a regular territorial kit. After the war, some were regular T.35s and others were Pirelli industrial variants with Dirin 600U filters

Fire Brigade. Before the war, T.35s issued to this corp had a regular territorial kit. After the war, some were regular T.35s and others were Pirelli industrial variants with Dirin 600U filters

Italian red cross. The red cross used the T.35 to prepare for eventual gas attacks. It was issued until the adoption of the M59, when it started slowly getting replaced

Italian red cross. The red cross used the T.35 to prepare for eventual gas attacks. It was issued until the adoption of the M59, when it started slowly getting replaced

Italian civilians could purchase civilian variants of the T.35 before the widespread sale of P.C. 40. Some critical civilian companies and industries were issued T.35s during the War and shortly before

Italian civilians could purchase civilian variants of the T.35 before the widespread sale of P.C. 40. Some critical civilian companies and industries were issued T.35s during the War and shortly before

Opera Nazionale Balilla (National Balilla operation, fascist youth). The T.35 was issued as a training mask for the short time both the T.35 and the ONB existed

Opera Nazionale Balilla (National Balilla operation, fascist youth). The T.35 was issued as a training mask for the short time both the T.35 and the ONB existed

Gioventù italiana del littorio (Italian lictorian youth, fascist youth). After the dissolution of the ONB the GIL carried on its training routine, until the end of the fascist regime

Gioventù italiana del littorio (Italian lictorian youth, fascist youth). After the dissolution of the ONB the GIL carried on its training routine, until the end of the fascist regime

Spain[]

Ejército de Tierra (Spanish army). The Spanish army used the T.35 in its recovered kit and refurbished variant after the Spanish Civil War with the designation of "L.T.35"

Ejército de Tierra (Spanish army). The Spanish army used the T.35 in its recovered kit and refurbished variant after the Spanish Civil War with the designation of "L.T.35"

Bando sublevado (Spanish Civil War nationalists). The T.35 was widely issued to nationalist troops, as Italy gifted more than 300.000 masks to this Army

Bando sublevado (Spanish Civil War nationalists). The T.35 was widely issued to nationalist troops, as Italy gifted more than 300.000 masks to this Army

Bando republicano (Spanish Civil War republicans). Republicans issued a lot of T.35 masks, especially after the battle of Guadalajara in March 1937, in which these masks were captured in a large number

Bando republicano (Spanish Civil War republicans). Republicans issued a lot of T.35 masks, especially after the battle of Guadalajara in March 1937, in which these masks were captured in a large number

Hungary[]

Légoltalmi liga (pre-Civil Defence).After the Bled agreement of 22 August 1938 Italy gifted some masks to Hungary. On 16 January 1939, the T.35 and T.33 with T.35 and Dirzepest filters went into service by Légoltalmi liga

Légoltalmi liga (pre-Civil Defence).After the Bled agreement of 22 August 1938 Italy gifted some masks to Hungary. On 16 January 1939, the T.35 and T.33 with T.35 and Dirzepest filters went into service by Légoltalmi liga

Hungarian industries. After the war, many industries purchased T.35 masks as surplus to be used either with a filter or to convert them for rebreather use

Hungarian industries. After the war, many industries purchased T.35 masks as surplus to be used either with a filter or to convert them for rebreather use

T.35 and the Media[]

The T.35 was so widespread that it found its way into multiple pieces of media, mostly Italian ones but with a few exceptions, some of which are listed below:

- The T.35 can be commonly found in Fallout 4 as the gas mask with goggles, although its presence there would be unlikely in real life, even without the hindrance of total atomic annihilation.

- A slightly inaccurate representation on the T.35 can be found in Battlefield 5 as the headpiece of the "Alpini" skin set. Note that the filter used is a French civilian one, which would not fit in the thread.

- The T.35 can be seen worn by Cristina Blackwater (model) in the Blood Shake musical video by Dope D.O.D and Salmo.

Videos[]

- 1958 colour video of firefighters training T.35 masks with DIRIN 600U filters can be seen after the 1:16 mark.

- 1935 Chemical protection exhibit The T.35 was shown for the first times in these exhibitions

- 1942 air-raid training T.35 masks can be seen amongst other masks in various scenes.

- Training in the mountains during the Second World War T.35 masks can be seen in the first part of this short video.

- Italian girls of the GIL parading, 1939 in the streets T.35 masks can be seen after 0:42 mark.

- 1973, Porto Maghera's strike to complain about the mandatory use of gas masks Various masks, including the T.35, can be seen being worn by protesters.

- Hungarian World News No. 819 Air defense practice in Budapest, Mg. gázálarc can be seen in use by BSzKRT and Légoltalmi Liga workers after 1:10.

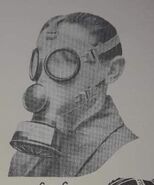

Pirelli T.35 manual[]

The pictures used in this manual are actually of a T.32 and not a T.35, but those two masks don't differ operationally so the same pictures could be used multiple times.

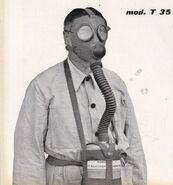

Spasciani T.35 manual[]

Spasciani-made manuals used pictures taken by Pirelli.